Despite over a decade of talk about “industrial digital transformation”, it’s only now we’re observing a tipping point. According to the VDC Research report Securing OT with Purpose-built Solutions, only 7.6% of surveyed industrial organizations consider themselves fully digital, but within two years 63.6% expect to be so. This shift is driven by two main factors: economic pressure pushing companies to radically increase efficiency, and the growing accessibility of technologies such as the industrial internet of things (IIoT) and edge computing.

Digitalization helps industrial enterprises boost both their efficiency and safety. Most organizations have already implemented asset, maintenance, and supply-chain management systems that reduce downtime and operating costs. More advanced technologies like digital twins and predictive analytics significantly improve processes, boost production, and cut waste of materials and resources. Integrating data from IT systems and ICS enables real-time decision-making based on up-to-date information.

But with integration comes vulnerability: systems that were once isolated or not digital at all become susceptible to IT failures and direct cyberattacks. Attacks on OT systems can lead to increased defect rates, failure of complex equipment, disruption of downstream production processes, and even catastrophic events that threaten worker safety. Even brief outages can have serious business consequences and damage a company’s reputation.

Major obstacles to industrial digitalization

According to the surveyed companies, cybersecurity concerns have become the main barrier to industrial digital transformation. Nearly 40% of the companies surveyed in the VDC report say they need to resolve this issue to move forward. Other top challenges include budget constraints and outdated equipment that’s too complex and expensive to upgrade for digital projects.

When it comes to security specifically, the top issues include a lack of resources for securing ICS equipment, inadequate security measures in existing infrastructure, and difficulties with regulatory compliance

The cost of an incident

When justifying cybersecurity budgets and planning for further development, experts unanimously recommend a risk-based approach tailored to the organization’s profile, its risk appetite, industry specifics, and other factors. The VDC Research report provides important data for this, documenting the nature and financial impact of security incidents in industrial organizations from 2023 to 2024. For example, 25% of surveyed companies that experienced security incidents with measurable financial consequences reported damages exceeding $5 million.

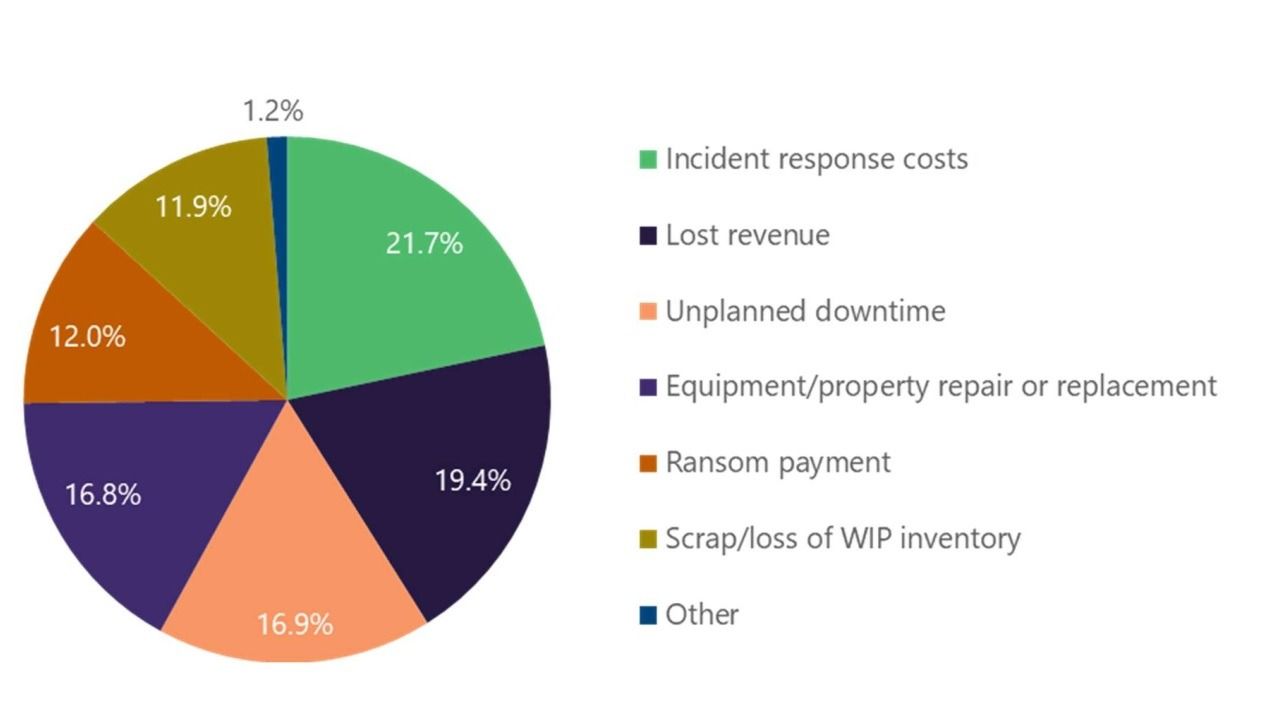

These costs include response efforts, direct revenue loss, and industrial-company-specific expenses like equipment repairs and losses of raw material or semi-finished goods. One of the top-three costs is unplanned downtime — a critical metric that industrial digitalization specifically aims to reduce. Most incidents resulted in downtime lasting 4–12 hours or 12–24 hours (with each range representing about a third of cases).

The cost breakdown is visualized below:

The challenges of protecting ICS

Despite the recognized need for ICS cybersecurity and regulatory requirements, implementation remains difficult. Almost every surveyed organization faces the following challenges:

- Limited visibility into OT networks due to numerous specialized communication protocols and incompatibility with standard IT monitoring tools

- A shortage of specialists skilled in working with proprietary systems and industrial protocols

- Insufficient network segmentation and the inability to isolate vulnerable equipment due to business needs; emergence of many new connections between IT and OT infrastructure

- A growing number of IIoT devices with insecure configurations and vulnerable firmware (manufacturers often neglect security)

- Outdated software and irregular patch releases

- Delayed patch installation due to the need for extensive testing and coordination with operations teams regarding the installation window

- Lack of detailed incident response plans that take into account critical events in OT networks

Some of these issues can’t be solved at the company level alone, but investing in specialized and integrated cybersecurity solutions can significantly mitigate the risks.

Specialized protection

While ICS protection projects are inherently complex, deploying specialized solutions purpose-built for OT/IT environments can increase efficiency and reduce risks. Key tools include asset and network traffic monitoring solutions (such as Kaspersky Industrial Cybersecurity for Networks) and endpoint protection solutions (such as Kaspersky Industrial Cybersecurity for Nodes). Organizations with mature cybersecurity programs use these as part of a defense-in-depth strategy — a multilayered security approach.

These solutions have features designed specifically for industrial networks, such as avoiding disruption of critical processes and communication, and operating with limited memory and processing power. This helps avoid meltdowns like the notorious CrowdStrike incident, where a careless security update disabled protected systems.

In the near future, technologies like SD-WAN and then SASE will play a bigger role by embedding security deeply into network architecture while ensuring resilience. Ultimately, the gold standard is a secure-by-design architecture, which should be built into smart industrial equipment by manufacturers at the outset.

Security implementation is a serious project — not just for the cybersecurity team but also for engineers and plant operators. As a result, project approval and rollout are often delayed. To reduce the burden on everyone involved, and also speed up the deployment of protection, companies should avoid a fragmented hodge-podge of security tools, and instead use comprehensive solutions from a single vendor. This simplifies both deployment and ongoing management through better integration. According to VDC’s survey, around 60% of organizations prefer getting all their security solutions from one provider.

How protection saves money

Despite the challenges, companies adopting specialized ICS protection solutions are already seeing clear economic benefits.

The VDC report shows that from 2023 to 2024, the number of incidents decreased in companies that deployed network and device monitoring tools. On average, incident rates dropped from 2.7 to 2.2 per year. Organizations using standard endpoint protection brought incidents down from 2.1 to 1.6. In contrast, industrial companies neglecting IT and OT protection experienced an average of 3.8 incidents — about twice as many as their better-protected competitors.

You can explore more about typical industrial digitalization projects, cyber incident damage estimates, and comprehensive protection recommendations in the full VDC report.

strategy

strategy

Tips

Tips